Instead of traditional kiln-made cement, an entirely new way of making the material has been discovered by two MIT scientists.

Research by an MIT startup found that using electricity in water starts a chemical reaction that forms the main ingredients in its cement – hydrated lime – without using fossil fuels.

In 2019 the team found that an electrolyser forms a pH gradient in a tank, with dissolved limestone on the acidic end and hydrated lime on the other. The lime is then combined with reactive silica to form the same compounds formed by traditional cement.

The team discovered other ways to make the chemical bonds that give concrete made with Portland cement its strength. Rather than alite, it uses lime and reactive silicates to react with water to form the final material.

Four years later Sublime Systems is running a pilot manufacturing line and in one week is able to make enough cement to fill a single concrete truck. The startup is making material to send to potential partners, running tests on cement blocks and helping to design future facilities.

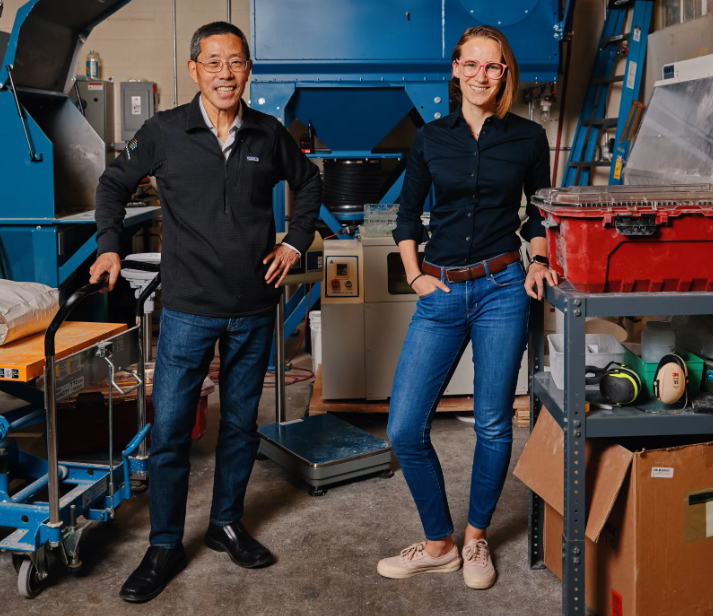

Sublime’s co-founder and CEO Leah Ellis says the material is as strong and durable as Portland cement – if not more so. Image: Professor Yet-Ming Chiang with Leah Ellis, co-founders of Sublime Systems.