The world’s first carbon captured net-zero cement will be manufactured on a large scale from 2025.

Being touted as “the future of construction” Heidelberg Materials, has released the product which will be available in two versions, depending on customer location.

Heidelberg is the parent company of Hanson Australia that operates 210 concrete plants across this country and owns a 50% stake in Cement Australia, its fellow Concrete Institute Gold member.

“Carbon capture, utilisation, and storage is a prerequisite for our industry to achieve net zero and vital to building the society of the future,” Dr Nicola Kimm, chief sustainability officer said.

Known as evoZero, Heidelberg revealed its Brevik plant in Norway will use the carbon capture and storage (CCS) technology with its net-zero footprint and transparent, traceable CO₂ capturing process, reviewed independently and secured by blockchain.

Brevik CCS is the world’s first carbon capture facility in a cement plant on a large scale, according to Heidelberg Materials. Mechanical completion of the facility is scheduled for the end of next year and once operational, 400,000 tonnes of CO₂ per year will be captured and stored, representing half of the plant’s emissions.

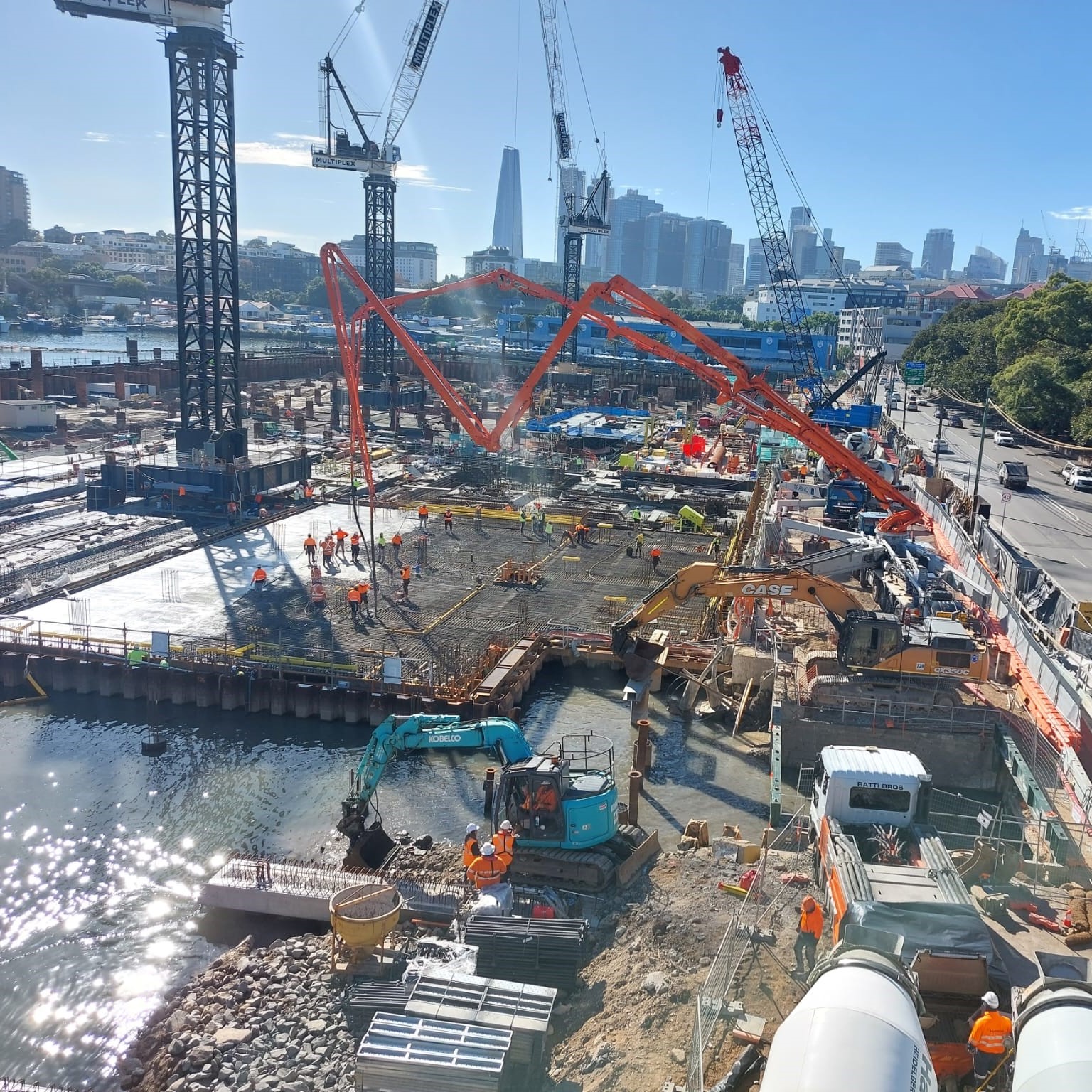

Image: Hanson Australia’s operations at the Sydney Fish Market project.