Researchers in Japan found a way to make concrete that they say effectively emits no carbon dioxide during the production process.

The research team from the University of Tokyo and Hokkaido University said the substance absorbs more carbon dioxide (CO₂) than it releases, according to The Asahi Shimbun website.

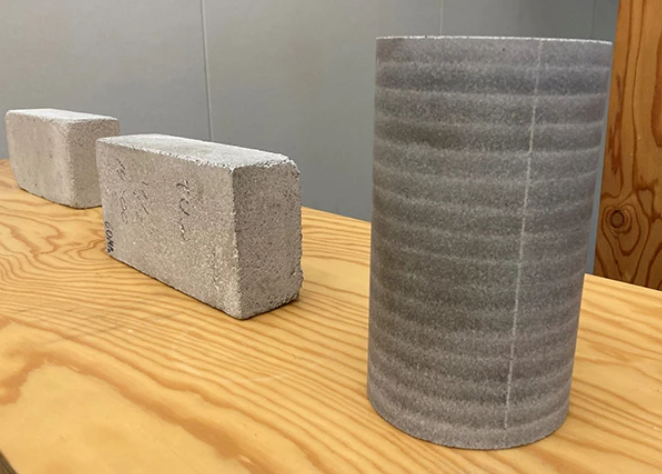

The concrete material, created by compressing calcium carbonate, has been named Calcium Carbonate Concrete (CCC) by its developers.

This production method involves pulverising concrete waste and exposing it to CO₂. The aim is to create calcium carbonate from the calcium in the waste. It is then shaped and compressed so the calcium carbonate particles bond and solidify. In the final stage, heat is applied to complete the process.

The researchers discovered that using this technique the concrete produced emits less CO₂ than it absorbs. A recent announcement revealed the concrete meets the strength criteria specified by Japan’s Building Standards Law and the team plans to work to improve production efficiency without compromising the quality of the material.

The new concrete is being evaluated for performance when combined with steel and other fittings used use in building pillars.